|

Method of “investment” or “lost wax” metal casting is

known since ancient times. The process is simple – a

master model or sculpture made of wax is being molded in

a one-time-use ceramic (clay or plaster) mold. After the

mold is cured, wax is being melted out of the mold and

metal is poured into the cavity. The mold than will be

broken in order to reveal the metal casting. Investment

casting method existed practically unchanged for

hundreds and hundreds of years and being used by

jewelers and sculptors. Method of “investment” or “lost wax” metal casting is

known since ancient times. The process is simple – a

master model or sculpture made of wax is being molded in

a one-time-use ceramic (clay or plaster) mold. After the

mold is cured, wax is being melted out of the mold and

metal is poured into the cavity. The mold than will be

broken in order to reveal the metal casting. Investment

casting method existed practically unchanged for

hundreds and hundreds of years and being used by

jewelers and sculptors.

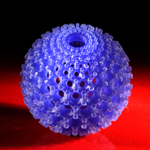

Development

of rapid prototyping gave a new life, form and purpose

to the ancient technique. One of the newest technologies

called Multi-Jet Modeling (MJM), patented by 3D Systems,

combined with use of new VisiJet® wax materials lead to

the ability to produce real wax patterns with extremely

high resolution. Development

of rapid prototyping gave a new life, form and purpose

to the ancient technique. One of the newest technologies

called Multi-Jet Modeling (MJM), patented by 3D Systems,

combined with use of new VisiJet® wax materials lead to

the ability to produce real wax patterns with extremely

high resolution.

Jewelry

industry was first to appreciate and adapt the new

technology. Master models of digitally designed jewelry

products could now be produced directly on ProJet

machines, in real wax, with precision, complexity and

amount of detailing like never before. A wax patterns

could be reproduced in quantities, remaining identical

and not losing quality due to re-cast.

ProJet technology was also recognized and adapted by

dentistry, precise instruments and medical industries

and product design community.

Due to the high cost a use of this technology in

professional model making is only justified for highly

paid projects. We moved to adopt this method as soon as

we learnt about it and believe that such quality and

ability to obtain so precise and detailed real metal

parts is worth paying for. Due to the high cost a use of this technology in

professional model making is only justified for highly

paid projects. We moved to adopt this method as soon as

we learnt about it and believe that such quality and

ability to obtain so precise and detailed real metal

parts is worth paying for.

So far the most logical application of precision

investment casting in model making is producing masters

for pewter casting.

Pewter (white metal) casting is a simple, efficient and

cost effective replication technique, adopted by

professional model makers and small manufacturers a long

time ago. Producing masters for pewter casting, that

would be able to withstand a temperature and pressure

while making a hard rubber mold, was a problem. Use of

precision investment casting combined with ProJet

technology made production of such masters hassle free.

We are sure that as this technology will be developed

further a cost of will be decrease and we will be able

to find more applications for high resolution real metal

parts and components. |